Amy Dindal points to extract vials in Battelle’s lab in Norwell, Massachusetts. Samples of AFFF remains from New Hampshire are seen labeled in green on the shelf below Dindal’s hand, awaiting testing for PFAS levels after a process worked to largely eliminate them from the water. (Photo by Trisha Nail)

This past summer, barrels upon barrels of foam used to extinguish fires were collected around New Hampshire and sent off to Ohio — 11,017 gallons, to be exact. But last month, remnants of the foam returned to New England to be tested in a laboratory in Norwell, Massachusetts.

Those gallons of foam contained PFAS (per- and polyfluoroalkyl substances), carcinogenic “forever chemicals” introduced to fire departments nationwide in the 1970s through aqueous film-forming foam (AFFF) that posed silent but harmful health risks to crews for decades. In June 2022, the NH Department of Environmental Services tracked down legacy AFFF inventory across the state’s fire departments and gathered it at 10 “AFFF Take Back” events in each of the state’s 10 counties.

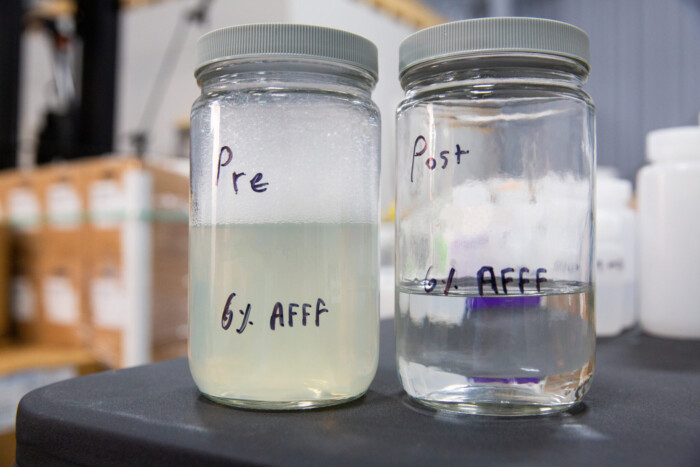

Then, in 2023, New Hampshire state officials partnered with Revive Environmental, a Columbus, Ohio-based firm, to have its team run the foam through its “PFAS Annihilator” method. Revive eliminates the substances from AFFF in a process known as supercritical water oxidation (SCWO). The business was spun off from the research of science and technology nonprofit Battelle to collect and destroy PFAS in various materials and filter chemicals from water using granular activated carbon.

Removing PFAS from foam

SCWO removes substances from AFFF and wastewater by heating the water beyond its boiling point and applying high pressure, according to Revive. This breaks down the carbon-fluorine bonds that form the “forever” quality of PFAS. Revive says it has demonstrated “more than 99.99% destruction of total PFAS on multiple occasions.” The company sent half a liter of its treated water to the Norwell lab, operated by the science and technology nonprofit Battelle.

The interior of one of Revive Environmental’s PFAS Annihilator units at the company’s Columbus, Ohio, facility is shown. (Courtesy Nathan Bierschenk)

Company president and CEO David Trueba told NH Business Review that the journey took about four months. Revive readied its team of staff to treat the foam six weeks after receiving the New Hampshire barrels, counted the volume over three days, and then needed a three-day period to decontaminate the foam and convert it into pure water.

“Processing it can take anywhere from a couple of hours for a five-gallon tote to a couple of days for a 270-gallon vessel,” he said. “It really depends on the type of material and the speed at which it processes through our system. Keep in mind that we’re about 60% of the speed we want to be; we’re going slow because these are our first customers on a large scale, and we want to do it the right way.”

It’s a small but mighty operation. As of mid-December, Revive employed just 32 people, 20 of whom operate machinery and process substances between facilities in Grand Rapids, Michigan, and Columbus. It’s delicate work, but the company has built PFAS-resistant labs with self-contained equipment to extract chemicals from the drum barrels.

“Even if we’ve had a spill, like when we were loading some of the New Hampshire material, I think we may have dripped less than a quarter of a cup on the floor, an epoxy-coated surface,” Trueba said. “We were able to immediately mop it up, put it into a hazardous disposal bin and we’re done.”

Trueba said even materials with high concentrations of PFAS, like AFFF, don’t immediately absorb into the skin on contact. However, employees wear PPE and routinely keep records of where materials are to avoid situations where that might be a concern. He said the state of New Hampshire has been receiving reports on when every 1,000 gallons of AFFF were processed — a sort of progress and accountability report.

Once the full 11,017 gallons underwent SCWO, Revive sent Battelle samples of treated water totaling 500 milliliters. The rest of the processed material is being held at Revive’s facilities while the company awaits the nonprofit’s findings. Results were not publicly available at the time of writing, but Battelle environment and agriculture business director Amy Dindal said turnaround time for samples at its lab is typically 28 days.

Sample jars show how AFFF looks before and after it is treated by Revive Environmental’s PFAS Annihilator. (Courtesy Revive Environmental)

“(Battelle) gives us the results, we then show that to our permit holder – the city of Columbus,” Trueba said. “The city says whether (PFAS levels) are what we could be below in our data, and then we get permission to put it into their sewer system. … Our discharge is actually cleaner than most industrial discharges. Even landfills have more PFAS in their leachate than we do.”

The city of Columbus granted Revive a “first-of-its-kind permit” to authorize the disposal of the PFAS-free water once Revive is ready, allowing residents three weeks to review the terms of the agreement before it was accepted.

Testing Revive’s efforts

New Hampshire officials are also awaiting the results of Battelle’s work, which began the second week of December once the sample arrived. Battelle’s team in Norwell is also relatively modest in size, with 50 employees — 30 of whom focus on laboratory work, according to Dindal.

Some of their staff have been involved with analyzing PFAS chemicals since 2009, when Dindal said foam emerging from water treatment systems at a military base was identified in Norwell as containing PFOA (perfluorooctanoic acid) and PFOS (perfluorooctane sulfonic acid), both designated hazardous substances by the U.S. Environmental Protection Agency in April 2024.

Battelle was the first lab to become accredited for PFAS testing methods in 2016 after the EPA declared a lifetime health advisory for PFAS, she said, leading to its research on how to destroy such substances launching in 2018.

“It’s been estimated that, based on what Revive has collected, there are about 200 different varieties of AFFF,” Dindal said, due to many manufacturers over the decades. “What we do for Revive is provide them analytical data to understand what those mixtures look like before they start to destroy it.”

Franco Pala, lab director at Battelle, took NH Business Review on a tour of how the nonprofit develops that data, beginning in its preparation lab. Coolers from Revive arrive with the samples, which are then transferred into vials and made more basic on the pH scale to be properly measured.

Once prepared, the extracted vials are taken to another laboratory, where chemist Denise Schumitz explains that an instrument separates any potential PFAS chemicals from the vials.

Battelle chemist Denise Schumitz describes how the nonprofit’s lab analyzes samples for PFAS, using the instrument at right. (Photo by Trisha Nail)

“We take that extract vial that Franco had, load it onto the instrument, and our auto-sampler will draw up a portion of that sample,” she said. “It runs it through what’s called an analytical column, takes the vial from the liquid to our detector, and turns it into a gas.”

If traces of PFAS are detected during this process, a peak appears on a graph called a chromatogram, which helps scientists determine any remaining levels of the chemical within the analyzed samples. Schumitz’s colleague, chemist Lauren Griffith, added that the space below the peaks is used to calculate the overall levels of PFAS, following a calibration process of measuring different vials with high and low concentrations.

Remnants of AFFF are just one material that Battelle tests to check whether they are PFAS-free. The nonprofit also works with manufacturers of consumer products like cat food and fishing pellets to check levels in those items, Pala said as he showed bagged samples of each material in the lab. Other studies continue to appear, highlighting new sources of “forever chemicals.”

“There are some scientific papers claiming that PFAS at ski resorts is coming from ski treatments like wax,” Pala said. “The important part the AFFF Take Back Program is doing is avoiding (the possibility) that PFAS goes into the water or in the soil or a landfill. If you don’t destroy that now, you will find it in the environment, and it will not be biodegraded in a reasonable time.”

Revive’s David Trueba said Ohio, Michigan, and New Hampshire are among the first states to partner with the company to remove PFAS from firefighting foam. He stated that negotiations are ongoing with at least seven states to quote pricing for future AFFF take-back programs.